Battery.

To better understand the operation of the ignition system`s primary circuits, we will start at the battery and trace the flow of electricity through the system. The battery is the source of electrical energy needed to operate the ignition system. The battery stores and produces electricity through chemical action. When it being charged, it converts electricity into chemical energy. When it is discharged (producing current), the battery converts chemical energy into electricity. To function properly, the battery must be in condition or charged to produce the highest output of electricity.

The primary circuit starts at the battery and flows to the ignition switch. It controls the flow of electricity across the terminals. The ignition switch may have additional terminals that supply electricity to other vehicle system when the key is turned on. Most ignition switches are installed on the steering column.

Some ignition system included a resistor in their primary circuits. Electricity flows from the ignition switch to the resistor. The resistors control the amount of current reaching the coil. It may be either the calibrated resistance wire or the ballast type.

Most resistors simply consist of a calibrated resistor wire built into the wiring harness between the ignition switch and coil. The resistance wire lowers battery voltage to around 9.5 volts during normal engine operation. However, when the engine is started, the coil receives full battery voltage from a bypass wire, the bypass wire supplies the coil with full battery voltage from the ignition switch and starter solenoid while the engine is cranking. when the key is released, the circuit receives its power through the resistance wire.

The ballast resistor, which is used on some vehicles is a temperature sensitive, variable resistance unit. A ballast resistor is designed to heat up at low engine speed as more current attempts to flow through the coil. As it Heats up, its resistance value increases, causing lower voltage to pass into the coil. As engine speed increases, the duration of current flow lessens. This causes a lowering of temperature. As the temperature drops, the resistor allows the voltage to the coil to increase.

At high speed, when a hotter spark is needed, the coil receives full battery voltage. The ballast resistor is a coil of nickel-chrome or nichrome wire. The nichrome wire`s properties tend to increase or decrease the voltage in direct proportion to the heat of the wire. The next figure illustrate some transistors ignition systems use two ballast resistors to control coil voltage. From the resistor, the current travels to the coil. Most moder vehicles with electronic ignition don`t use a resistor in the ignition circuit. The majority of modern electronic ignition systems use full battery voltage at all times.

Ballast resistor principles. A-- This illustrates long pulsation of

current passing through a special ballast resistor wire at slow

engine speeds. The current heats the special wire and lowers

amount of current reaching coil, B--This illustrate short pulsation

at high speeds. This allows wire to cool, and a heavier current

to flow the coil.

Ignition Coil.

The primary circuit leads from the ignition switch or resistor to the ignition coil. An ignition coil is actually a transformer that is capable of increasing battery voltage to as much as 100,000 volts, although most coils produce about 50,000-60,000 volts. Coils vary in size and shape to meet the demands of different vehicles.

Coil Construction.

The coil constructed with a special laminated iron core. Around this central core, many thousands of turns of very fine copper wire are wound. This fine wire is covered by a thin coating of high temperature insulating varnish. One end of the fine wire is is connected to the high tension terminal and the other is connected to the primary circuit wire within the coil. All these turns of fine wire from what is called the secondary winding.

Several hundred turns of heavier copper wire are wrapped around the secondary coil winding. Each end is connected to a primary circuit terminal on the coil. This winding are also insulated. The turns of heavier wire from the primary winding.

The core with both the secondary and primary winding attached is placed inside a laminated iron shell. The job of the shell is to help concentrate the magnetic lines of force that will be developed by the windings. This entire unit is then placed inside a steel, aluminum, or bakelite case. In some coil designs, the case is filled with oil or paraffin-like material In other designs, the coil windings are encased in heavy plastic. The coil is sealed to prevent the entrance of dirt or moisture. The primary and secondary terminals are carefully sealed to withstand vibration, heat, moisture, and the stresses of high induced voltage.

Several different ignition coils and their construction.

A- A remote mounted high energy ignition coil (HEI)

B-Cutaway view of HEI coil construction.

C-Cutaway view of a conventional style coil.

Coil Operation.

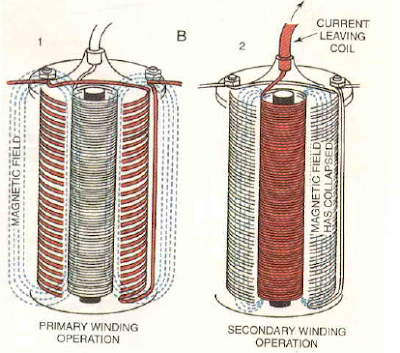

When the ignition switch is turned on, the current flows through the primary windings of the coil to ground. When a current flows through a wire, a magnetic field is built up around the conductor. Since there are several hundred turns of wire in the primary windings, a strong field is produced. This magnetic field surrounds the secondary as well as the primary windings. If there is a quick and clean interruption of current flow on its way to ground after passing through the coil, the magnetic field will collapse into the laminated iron core.

As the fields collapses through the primary winding, the voltage in the primary windings will be increased. This is called self-induction, since the primary windings produce its own voltage increase. The voltage induced in the primary windings is about 200 volts. Since it consists of only several hundred turns of wire, self-induction does not affect secondary winding operation, but can cause point arcing on contact point system.

As the magnetic field collapses, it passes through the secondary winding, producing a tiny current in each turn. The secondary windings posses thousands of turns of wire, since the are in seies, the voltage of each turn of wire is multiplied by the number of turns. This can produce a voltage exceeding 100,000 volts. This is known as induction. The high voltage produced by the secondary windings exits the high tension coil terminal and is directed to the spark plugs.

Most coils have primary terminals marked with a (+) and (-). The plus sign indicates positive and minus indicates negative. The coil must be installed in the primary circuit according to the way the battery is grounded. This alignment of the positive and negative terminals is grounded, the negative terminal of the coil must be connected through the ignition module or distributor to ground as applicable. This is done to ensure the correct polarity at the spark plug.

Wiring schematic illustrating how the coil induces current

flow in a secondary coil.

Ignition coil operation. 1-primary winding. 2- Secondary

winding. Current is now leaving the coli in its way to spark

plugs via distributor.

Actual Coil Output.

Even though the voltage output of some coils can exceed 100,000 volts, the coil will only build enough voltage to produce the spark. This may be as low as 2000 volts at idle on older vehicle without emission controls or as high as 60,000 volts on a new vehicle with the leanest possible mixture and under a load. To control the coil`s output, most engines have a distributor. The job of the distributor is to trigger the coil and to distribute the high voltage current to the right spark plug at the right time.

Collapse of primary field. When the primary circuit

is broken, the magnetic field will collapse through

secondary winding to the core.

Methods of current interruption.

To cause coil`s magnetic field to collapse, the current flow through the primary windings must be interrupted instantly and cleanly with no flash-over (current jumps or arcs across space) at the point of disconnection for about 75 years, The primary current flows was controlled by using a set of contact points to break points flow anf collapse the coil primary field. Over the last 20 years, contact point systems have been placed by electronic ignition systems, which uses transistors to operate the primary circuit.

Electronic ignition can produce the high voltage spark needed to fire the leaner mixtures used on modern vehicles. While the old contact point point system could produce no more than 20,000 or 30,000 volts, electronic ignition systems allow as much as 100,000 volts to be used. All modern vehicles use ignition systems with electronic primary circuit control, the basic difference between contact point ignition systems and electronic ignition systems is the method employed to interrupt the coil primary circuit.

Contact point.

The contact points used on older vehicles were a simple mechanical way of making and breaking the coil primary circuit. The stationary piece is grounded through the distributor contact point mounting plate. This section does not more other than for an initial point adjustment.

The second piece is the movable contact point. It is pivoted on a steel post. A fiber spring presses the movable contact arm against the stationary unit, causing the two contact points to touch each other. The movable arm is pushed outward by the distributor cam lobes, which are turned by the distributor shaft opens and closes the points as it revolves. The numbers of lobes corresponds to the number of cylinders.

Typical contact point construction. Most incorporate the adjustable

point into an adjustable support base. Average point gap specification

(.018`` to .022``)

The cam rotates and moves the contact arm through a fiber rubbing block. This is fastened to the contact arm and rubs against the cam. High temperature lubricant is used on the block to reduce wear. The movable contact arm is insulated so that when the primary circuit will not be grounded the contact points are touching.

Contact Point Dwell.

The number of degrees the distributor cam rotates from the time points close until they open again is called dwell and is sometimes referred to as it affects the magnetic build up of the primary windings. The longer the points are closed, the greater the magnetic build up. However too much dwell can result in point arcing and burning. If the dwell is too small, the points will open and collapse the field before it has built up enough voltage to produce a satisfactory spark.

When setting contact point gabs, as the gab is reduced, dwell is increased. When the gab is enlarged, dwell is decreased. The dwell cannot be adjusted on electronic ignition systems, but can be measured as an aid to diagnosis. Always check the manufacturer`s specification for dwell when setting points.

These ignition points close at 1 and remain closed as cam rotates

to 2. The number of degrees formed by this angle determines

dwell.

Condenser.

The condenser, sometimes called a capacitor, absorbs excess primary current when the contact points are opened. The condenser prevents point arcing and resulting overheating, pitting, and excessive wear. In addition to increase contact point service life, the condenser allows the coil`s magnetic field to collapse quickly, producing a strong instant spark.

Most condensers are constructed of two sheets of very thin foil separated by two or three layers of insulation. The foil and insulation are wound together into a cylinderical shape. The cylinder is then placed in a small metal case and sealed to prevent the entrance of moisture. The close placement of the foil stripes creates capacitance, or the ability to attract electrons.

When the points are closed, the condenser is in active as the coil`s magnetic field begins to build in strength when the points open, the magnetic field begins to collapse and voltage in the primary windings increase due to self induction. If a condenser was not used, the voltage in the primary circuit would arc across the points, consuming the coil`s energy before the magnetic field passes through the secondary windings.

However, the condenser attracts the excess primary voltage, preventing an arc across the points. By the time the condenser has become fully charged, the points have opened too far the current to arc the magnetic field collapse through the secondary windings, producing a quick strong spark.

The condenser unit is hermetically sealed in a metal case. Note

how the condenser is attached in the distributor.

Electronic Ignition.

The schematic in the figure is a simple electronic ignition circuit. Note that there are no mechanical devices to make and break the circuit. The entire process is done electronically. Current flows from the ignition switch, through the ignition module, to the coil. The ignition module contains the electronic components which cause the coil to produce a high voltage spark. Ignition modules process the inputs from other ignition components.

Schematic showing power flow through one type of electronic

ignition circuit.

Ignition modules are sometimes installed on the engine firewall or inner fender to protection them from excessive engine heat. Other modules are located in the distributor, installed outside on the distributor body, or as part of the coil assembly. Current from ignition switch enters the module and passes through a power transistor before reaching the coil. The power transistor acts like a conductor, allowing full current to flow in the circuit. This begins the build up of the magnetic field in the coil.

When the power transistor is signaled by triggered device and other module circuitry, it becomes an insulator. Since current flow through an insulator, this stops current flow through the coil primary circuit. When current flow stops, the magnetic field collapses, creating the high voltage current in the secondary windings. After the coil collapse is complete, the process is repeated as current flow through the power transistor begins again.

A&B--Exploded views of distributor assembly which house

electronic ignition module.

C--Ignition system schematic showing an electronic

ignition module.

Electronic Triggering Devices.

Electronic triggering devices send a signal current to the ignition module, which then breaks the primary circuit. The parts of triggering device don`t wear, which gives them a much longer life expectance than contact points, since the triggering device does n`t change. The improves engine performance, emission output, and reliability. There are three types of triggering devices currently in use:

- Magnetic.

- Hall effect.

- Optical.

Most of the triggering devices are operated by rotation of the distributor shaft. Some triggering devices are installed into or on the engine block and operated by the rotation of the crankshaft and/or camshaft.

Magnetic Pickup.

The magnetic pickup is mounted in the distributor and reacts to distributor speed, which is one half of crankshaft speed, this sensor generates alternating current. The current produced is small (about 250 millivolts) but can be read easily by the ignition module. The rotating tooth assembly is called a relutor, or trigger wheel. The stationary assembly is called the pickup coil or stator .

An air gab between the rotating and stationary teeth prevents physical contact and eliminates wear. When a tooth of the reluctor aligns with the tooth of the pickup, a voltage signal is sent to the ignition module, which turns the power transistor off and interrupts primary current to the ignition coil, causing it to fire a spark plug. Some sensors are mounted near the crankshaft. a reluctor wheel is part of the crankshaft and is placed at its midpoint. An air gap also exists between this sensor and reluctor. When the sensor is the middle of each slot, the transistor is turned of and interrupts current flow to the ignition coil, causing a spark plug to fire. The air gap is critical on all magnetic sensors and must be set to specification.

Several different magnetic crankshaft position

sensors. A--An air gap exists between the

reluctor and pickup coil. Mounted on the distributor

B--An alternating current pattern is produced by this

sensor. C-- A position sensor and reluctor located at

the crankshaft.

Hall Effect Switch.

The hall-effect switch can be mounted in the distributor or at the crankshaft, The hall-effect sensor is a thin wafer of semiconductor material with voltage applied to it constantly. A magnet is located opposite the sensor.There is an air gap between the sensor and magnet. The magnetic field acts on the sensor until a metal tab, usually called a shutter, is placed between the sensor and magnet. This metal tab does n`t touch the magnet or sensor. When contact between the magnetic field and sensor is interrupted, it causes its output voltage to be reduced. This signals the ignition module to turn the power transistor off. This interrupt primary current to the ignition coil, causing it to fire.

A--A magnetic field can act on a Hall-Effect sensor.

B-When the metal tab attached to the distributor shaft

rotates between the magnet and hall-effect sensor, the

magnetic field is interrupted. The ignition coil send high

voltage to the distributor any time the magnetic field is

interrupted

Optical Sensor.

The optical sensor is usually located in the distributor. The rotor plate has many slits in it through which light passes from the light emitting diode (LED) to the photo sensitive diode (light receiving ). As the rotor plate turns, it interrupts the light beam from the LED to the photo diode. When the photo diode does not detect light, It sends a voltage signal to the ignition module, causing it to fire the coil.

An optical crankshaft position sensor uses an LED to send a beam

of light to a photo diode through slits in a rotor plate.

A rotor plate used with the optical sensor. Note the spacing of the

slits.

Distributorless Ignition System.

The distributorless ignition system has no distributor. It uses a crankshaft position sensor, which is a magnetic pickup of Hall-Effect switch. The crankshaft sensor is mounted on or in the engine block. Some distributorless systems have a second sensor on the camshaft. the sensor performs the same job that the pickup coil or Hall-Effect switch does in the distributor, match stroke. The advantage of this system is the elimination of the distributor or assembly, rotor, and distributor cap.

An electrical signal is generated when ever the crankshaft is rotating and the signal is sent to the ignition module and/or on-board computer. This signal allows the computer to determine the position of each piston in the engine. On systems with crankshaft and camshaft sensors, both sensor readings are used to determine piston position. The sensor input may also used by the computer to determine engine RPM and the amount of ignition timing advance.

A-- An electronic distributorless ignition system schematic.

B-- One possible arrangement of components for a distributorless ignition system.

The distributorless ignition creates a high voltage spark plug using multiple ignition coils. There is one ignition coil for every two cylinders. A four-cylinder version has two coils, a six-cylinder has three coils, and a V-B uses four coils multiple coils must be used since there is no distributor cap and rotor to distribute the spark.

All distributorless ignition coils have two discharge terminals. These terminals are connected to two of the engine spark plugs through conventional resistor plug wires. Where the coil fires, the spark exits one terminal, travel through the plug wire to fire the plug, and returns to the other coil terminal through the engine block, the other other spark plug wire in effect the coil fires both plugs at the same time. The coil wires are arranged so that the coil fires one plug on the top of the exhaust stroke has no effect on the operation of the engine and is often called a waste spark. Since it takes very little voltage to jump the spark plug gab on the exhaust stroke, the coil is powerful enough to fire both plugs.

A integrated direct ignition system is a variation of the distributorless ignition system. This system uses conductor strips instead of spark plugs wires to transfer electricity from coils to the spark plugs. As in all distributorless systems, each coil serves two spark plugs.

Exploded view of a direct ignition system. This two-coil

setup for use with four-cylinder engine.

Direct Ignition System.

A direct ignition system is similar to a distributorless ignition system. However, there is one coil for each spark plug in a direct ignition system. Spark plug wires or other conductors are not used between the coils and the plugs. Instead, the coil towers are connected directly to the spark plugs.

Exploded view showing the coil and spark plug

arrangement for one cylinder of V-B engine with

direct ignition. Each plug in this engine have its

own coil.

You have now traced the flow of current through the primary system.

After going through the contact module or contact points, it returns to

the battery through the metal parts of the vehicle to which it is grounded.